Modern industrial applications demand reliable sealing solutions that minimize downtime and reduce maintenance complexity. Cartridge Mechanical Seals have emerged as the preferred choice for engineers and maintenance professionals seeking efficient, cost-effective sealing systems. These advanced sealing solutions offer significant advantages over traditional component seals, particularly in terms of installation simplicity and operational reliability. The streamlined design of these systems eliminates many common installation challenges while ensuring optimal performance across diverse industrial applications.

Understanding the Design Advantages of Cartridge Sealing Systems

Pre-Assembled Configuration Benefits

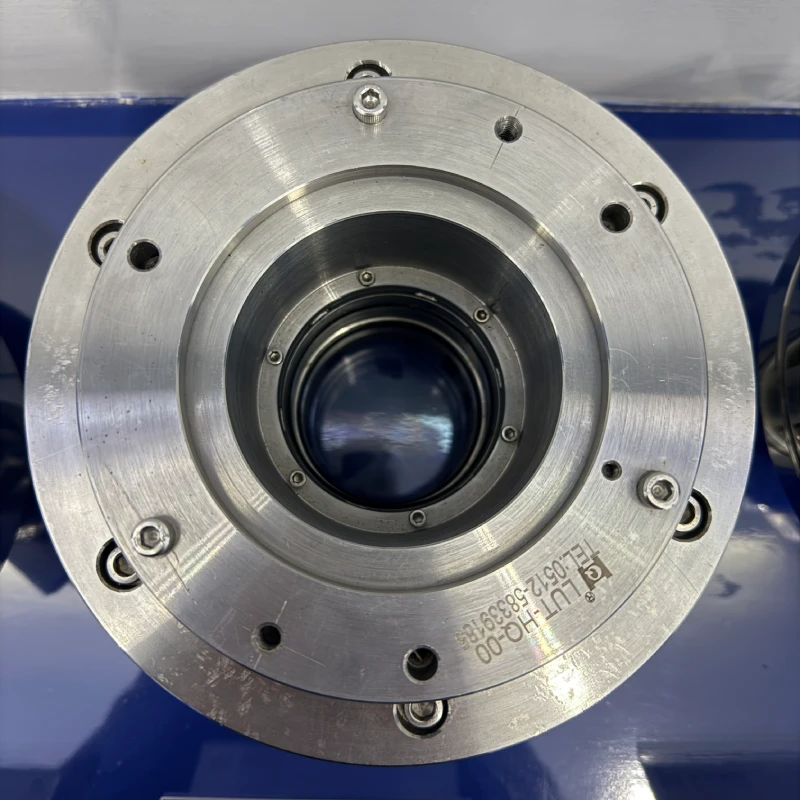

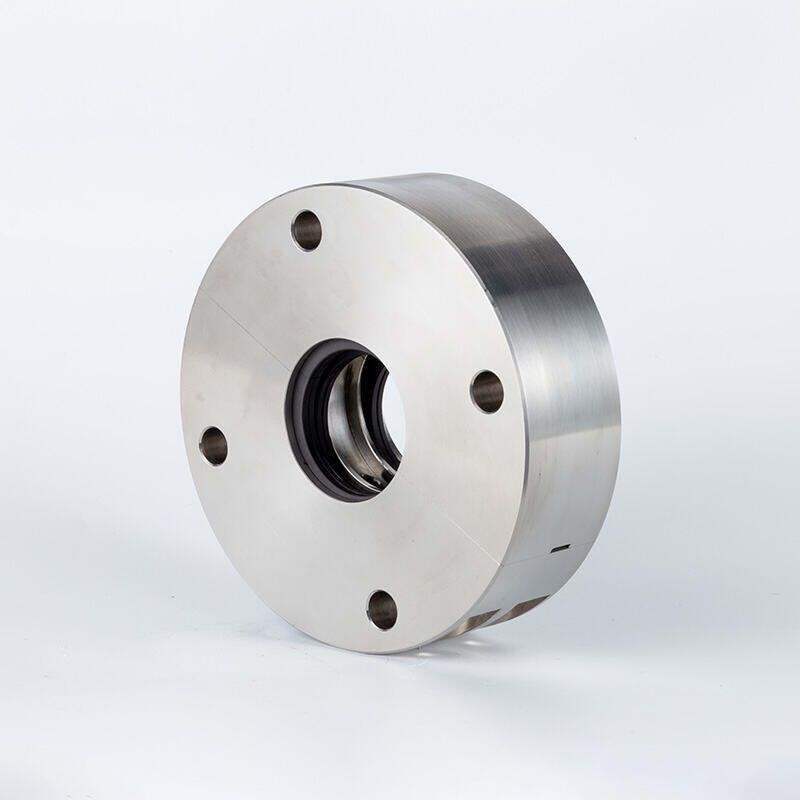

The fundamental advantage of Cartridge Mechanical Seals lies in their pre-assembled configuration. Unlike traditional component seals that require individual installation of multiple parts, cartridge systems arrive as complete units ready for installation. This pre-assembly eliminates the risk of improper component alignment and reduces the potential for human error during installation. Manufacturing facilities benefit significantly from this approach as it reduces the skill level required for maintenance personnel while ensuring consistent seal performance.

The integrated design includes all necessary components within a single housing, including the seal faces, springs, gaskets, and hardware. This comprehensive approach means that maintenance teams no longer need to stock multiple individual components or worry about compatibility issues between different seal elements. The result is simplified inventory management and reduced procurement complexity for industrial facilities.

Precision Engineering and Quality Control

Modern Cartridge Mechanical Seals undergo rigorous quality control processes during manufacturing that would be impossible to replicate during field assembly. The controlled manufacturing environment allows for precise tolerances and optimal component alignment that directly translates to improved seal performance and longevity. Advanced manufacturing techniques ensure that critical dimensions are maintained within exact specifications, eliminating variables that could compromise seal integrity.

The factory setting enables comprehensive testing and validation of each seal assembly before shipment. This quality assurance process includes pressure testing, leak detection, and performance verification under simulated operating conditions. Such thorough testing provides confidence in seal performance and reduces the likelihood of premature failures that could result from improper field assembly.

Installation Process Simplification and Time Reduction

Streamlined Installation Procedures

The installation of Cartridge Mechanical Seals follows a straightforward process that significantly reduces installation time compared to component seals. The typical installation involves removing the old seal, cleaning the shaft and seal chamber, and installing the new cartridge unit as a complete assembly. This simplified process eliminates the need for complex measurements, adjustments, and alignments that are required with traditional sealing systems.

Installation personnel no longer need specialized tools or extensive training to properly install these sealing systems. The standardized installation process reduces the potential for errors and ensures consistent results regardless of the technician's experience level. This standardization is particularly valuable for facilities with multiple locations or those that rely on contract maintenance services.

Reduced Downtime and Operational Efficiency

The time savings associated with cartridge seal installation directly translates to reduced equipment downtime and improved operational efficiency. While traditional component seals may require several hours for proper installation and adjustment, Cartridge Mechanical Seals can typically be installed in a fraction of that time. This time reduction is critical for industrial processes where equipment downtime represents significant cost implications.

The reduced installation time also allows maintenance teams to complete more repairs during scheduled maintenance windows, improving overall equipment availability. This efficiency gain is particularly important for critical process equipment where extended downtime could impact production schedules or compromise safety systems.

Technical Specifications and Performance Characteristics

Material Selection and Compatibility

Modern Cartridge Mechanical Seals utilize advanced materials specifically selected for compatibility with diverse industrial fluids and operating conditions. The material selection process considers factors such as chemical compatibility, temperature resistance, wear characteristics, and environmental conditions. Common materials include silicon carbide, tungsten carbide, and various elastomer compounds designed to withstand challenging operating environments.

The controlled manufacturing environment allows for precise material application and quality control that ensures optimal performance characteristics. Advanced coating technologies and surface treatments are applied under controlled conditions to enhance wear resistance and extend seal life. These manufacturing advantages contribute to superior performance compared to field-assembled alternatives.

Operating Parameters and Application Range

Cartridge Mechanical Seals are designed to operate effectively across wide temperature and pressure ranges, making them suitable for diverse industrial applications. Typical operating parameters include temperatures from -40°C to 400°C and pressures up to 40 bar, depending on the specific seal design and materials. The robust construction enables reliable operation in applications involving abrasive fluids, high temperatures, and challenging chemical environments.

The versatility of these sealing systems makes them suitable for applications ranging from chemical processing and petroleum refining to food and beverage production. The standardized design approach allows for consistent performance across different applications while maintaining the installation simplicity that defines cartridge seal technology.

Maintenance Benefits and Long-Term Cost Considerations

Preventive Maintenance Advantages

The simplified design of Cartridge Mechanical Seals contributes to more effective preventive maintenance programs. The reduced complexity eliminates many potential failure points associated with traditional sealing systems, allowing maintenance teams to focus on other critical equipment components. The predictable performance characteristics enable more accurate maintenance scheduling and inventory planning.

Maintenance personnel can quickly assess seal condition without disassembly, enabling proactive replacement before failure occurs. This capability reduces the risk of catastrophic seal failures that could result in equipment damage or environmental releases. The improved maintenance visibility contributes to enhanced safety and environmental compliance for industrial facilities.

Total Cost of Ownership Analysis

While Cartridge Mechanical Seals may have higher initial costs compared to component seals, the total cost of ownership typically favors the cartridge approach. The reduced installation time, lower skill requirements, and decreased inventory complexity contribute to significant cost savings over the seal's operational life. Additional savings result from reduced equipment downtime and improved seal reliability.

The extended service life of properly installed cartridge seals further enhances their cost effectiveness. The controlled manufacturing environment and precision assembly typically result in longer operational periods between replacements compared to field-assembled alternatives. This extended service life reduces both direct replacement costs and indirect costs associated with maintenance activities.

Industry Applications and Performance Validation

Chemical Processing and Petrochemical Industries

The chemical processing industry has widely adopted Cartridge Mechanical Seals due to their reliability in handling corrosive and hazardous fluids. The sealed cartridge design provides enhanced containment compared to traditional sealing methods, contributing to improved safety and environmental compliance. The consistent performance characteristics are particularly important in processes involving toxic or environmentally sensitive materials.

Petrochemical facilities benefit from the reduced maintenance requirements and improved reliability of cartridge sealing systems. The ability to quickly replace seals during turnarounds minimizes downtime and reduces maintenance costs. The standardized installation process enables consistent results across different units and locations within large industrial complexes.

Water Treatment and Municipal Applications

Municipal water treatment facilities have increasingly adopted Cartridge Mechanical Seals for critical pumping applications. The simplified maintenance requirements are particularly valuable for facilities with limited maintenance resources or remote locations. The improved reliability contributes to consistent water supply and treatment operations that are essential for public health and safety.

The standardized design of these sealing systems enables effective spare parts management across multiple facilities within municipal systems. The reduced skill requirements for installation and maintenance make these systems particularly suitable for facilities that may not have specialized maintenance personnel on staff continuously.

Future Developments and Technology Trends

Advanced Materials and Design Innovations

Ongoing research and development efforts continue to enhance the performance and capabilities of Cartridge Mechanical Seals. Advanced ceramic materials and nanocoatings are being developed to extend service life and improve performance in extreme operating conditions. These material innovations promise to further expand the application range and improve cost effectiveness of cartridge sealing technology.

Smart sensor integration is emerging as a significant trend in cartridge seal development. These sensors can provide real-time monitoring of seal condition, enabling predictive maintenance strategies and further reducing the risk of unexpected failures. The integration of monitoring technology with simplified installation procedures represents the next evolution in sealing system technology.

Sustainability and Environmental Considerations

Environmental sustainability considerations are driving continued improvements in Cartridge Mechanical Seals design and manufacturing. Recyclable materials and environmentally friendly manufacturing processes are being implemented to reduce the environmental impact of seal production and disposal. These sustainability initiatives align with broader industrial trends toward environmental responsibility and circular economy principles.

The improved reliability and extended service life of cartridge seals contribute to reduced material consumption and waste generation compared to traditional sealing methods. This environmental benefit, combined with the operational advantages, makes Cartridge Mechanical Seals an attractive choice for companies seeking to improve their environmental performance while maintaining operational efficiency.

FAQ

What makes cartridge seals easier to install than component seals?

Cartridge Mechanical Seals come pre-assembled with all components properly aligned and tested, eliminating the need for field assembly and adjustment. This pre-assembly reduces installation time, minimizes the potential for human error, and ensures consistent performance regardless of the technician's skill level.

How do cartridge seals reduce maintenance costs?

The simplified installation process reduces labor costs and equipment downtime during maintenance activities. Additionally, the improved reliability and longer service life of cartridge seals reduce the frequency of replacements and associated maintenance activities, contributing to lower total cost of ownership.

Are cartridge seals suitable for high-pressure applications?

Yes, modern Cartridge Mechanical Seals are designed to operate effectively at pressures up to 40 bar or higher, depending on the specific design and materials used. The controlled manufacturing environment enables precise tolerances and robust construction that can withstand demanding pressure conditions.

What industries benefit most from cartridge seal technology?

Chemical processing, petrochemical, water treatment, food and beverage, and pharmaceutical industries benefit significantly from cartridge seal technology due to the combination of reliability, safety, and maintenance simplicity these systems provide. Any application requiring reliable sealing with minimal maintenance complexity can benefit from cartridge seal installation.

Table of Contents

- Understanding the Design Advantages of Cartridge Sealing Systems

- Installation Process Simplification and Time Reduction

- Technical Specifications and Performance Characteristics

- Maintenance Benefits and Long-Term Cost Considerations

- Industry Applications and Performance Validation

- Future Developments and Technology Trends

- FAQ