In industrial applications where reliability and performance are paramount, double mechanical seals have emerged as the preferred sealing solution for high-pressure and high-temperature environments. These advanced sealing systems provide superior protection against leakage, contamination, and equipment failure, making them essential components in critical industrial processes. Understanding the capabilities and applications of double mechanical seals is crucial for engineers and facility managers seeking optimal performance in demanding operational conditions.

Advanced Design Principles of Double Mechanical Seals

Dual Face Configuration Benefits

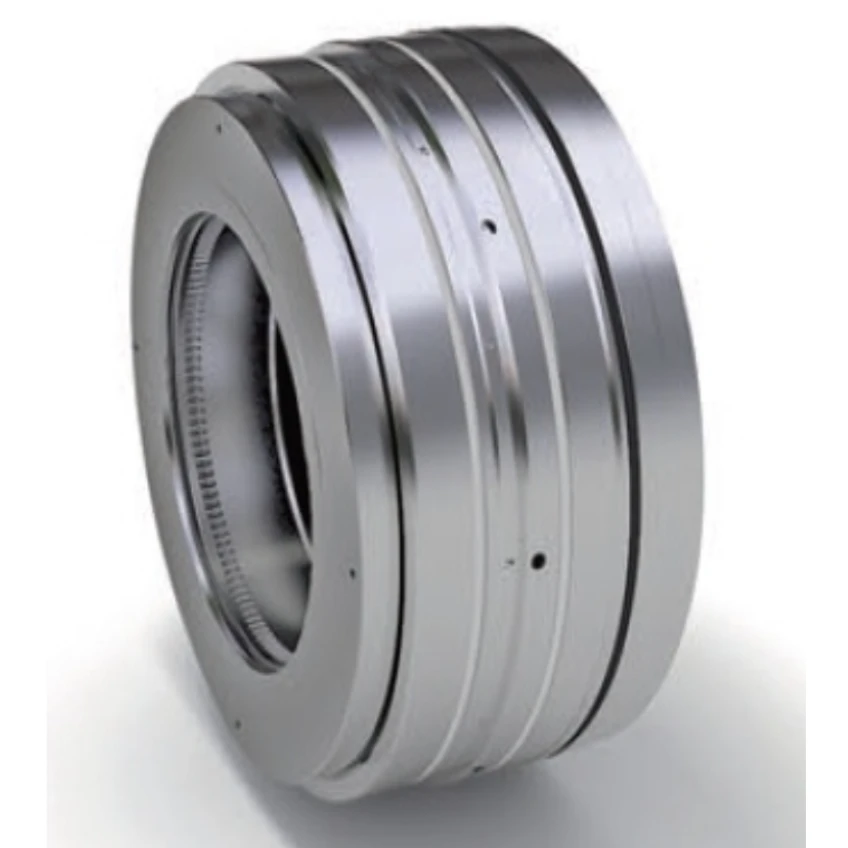

Double mechanical seals incorporate two distinct sealing faces that work in tandem to provide enhanced protection and reliability. This dual-face configuration creates a barrier system that significantly reduces the risk of process fluid leakage while maintaining optimal performance under extreme conditions. The primary seal face handles the process fluid directly, while the secondary face provides an additional layer of protection against environmental contamination.

The innovative design of double mechanical seals allows for independent operation of each sealing interface, ensuring that if one seal experiences wear or damage, the secondary seal continues to provide protection. This redundancy is particularly valuable in applications where unscheduled downtime could result in significant operational losses or safety concerns.

Enhanced Pressure Management Capabilities

The pressure management capabilities of double mechanical seals far exceed those of single mechanical seals, making them ideal for high-pressure applications. The dual sealing arrangement distributes pressure loads across multiple surfaces, reducing stress concentration on individual components and extending overall seal life. This pressure distribution mechanism enables double mechanical seals to operate effectively in systems with pressures exceeding 300 PSI.

Advanced pressure management features include specialized spring systems and balanced seal face geometries that maintain optimal contact pressure throughout the operational range. These design elements ensure consistent sealing performance even when system pressures fluctuate during normal operation or transient conditions.

Temperature Control and Thermal Management

Superior Heat Dissipation Technology

Temperature control represents one of the most significant advantages of double mechanical seals in high-temperature applications. The dual sealing arrangement creates multiple heat dissipation paths, allowing for more effective thermal management compared to single seal configurations. This enhanced heat dissipation capability enables double mechanical seals to operate reliably at temperatures up to 500°F in many applications.

The thermal management system incorporates specialized materials and coatings that maintain dimensional stability and surface integrity at elevated temperatures. These materials resist thermal expansion and contraction cycles that could otherwise compromise seal performance and lead to premature failure.

Barrier Fluid Cooling Systems

Many double mechanical seals utilize barrier fluid systems that provide additional temperature control and lubrication benefits. These barrier fluids circulate between the primary and secondary seal faces, carrying away heat generated by friction and providing continuous lubrication to critical sealing surfaces. The barrier fluid system also prevents process contamination and extends seal operating life.

The selection of appropriate barrier fluids depends on the specific application requirements, including temperature range, chemical compatibility, and environmental considerations. Common barrier fluids include synthetic oils, glycol solutions, and specialized heat transfer fluids designed for extreme temperature conditions.

Industrial Applications and Performance Benefits

Chemical Processing and Petrochemical Industries

Chemical processing facilities rely heavily on Double Mechanical Seals for critical pumping applications involving corrosive chemicals, high-temperature processes, and hazardous materials. These sealing systems provide the reliability and safety margins necessary to prevent environmental releases and protect personnel from exposure to dangerous substances.

The dual sealing configuration offers particular advantages in applications where process fluid contamination must be prevented at all costs. Chemical reactors, distillation columns, and transfer pumps benefit significantly from the enhanced protection provided by double mechanical seals, especially when handling volatile organic compounds or toxic materials.

Power Generation and Steam Applications

Power generation facilities utilize double mechanical seals extensively in steam systems, cooling water circuits, and auxiliary equipment where high temperatures and pressures are common. The robust design of these sealing systems ensures reliable operation in demanding utility environments where equipment failure could impact power generation capacity.

Steam turbine applications present unique challenges that double mechanical seals are specifically designed to address. The combination of high temperature, pressure cycling, and potential for steam condensation requires sealing solutions that maintain performance throughout varying operational conditions.

Material Selection and Compatibility Considerations

Advanced Seal Face Materials

The performance of double mechanical seals depends significantly on the selection of appropriate seal face materials that can withstand the specific operating conditions. Silicon carbide, tungsten carbide, and specialized ceramic materials offer excellent wear resistance and thermal stability for demanding applications. These advanced materials maintain their sealing properties even when exposed to abrasive particles or chemically aggressive process fluids.

Material compatibility extends beyond the seal faces to include secondary sealing elements such as O-rings, gaskets, and spring components. The selection process must consider chemical resistance, temperature limits, and mechanical properties to ensure long-term reliability of the complete sealing system.

Elastomer and Secondary Seal Selection

Secondary sealing elements in double mechanical seals play crucial roles in maintaining system integrity and preventing bypass leakage. Fluorocarbon elastomers, perfluoroelastomers, and specialty compounds provide the chemical resistance and temperature stability required for extreme service conditions. The proper selection of these materials ensures compatibility with both process fluids and barrier fluid systems.

Advanced elastomer compounds offer enhanced resistance to explosive decompression, chemical attack, and thermal degradation. These properties are essential in applications where double mechanical seals must maintain sealing integrity throughout extended service intervals and challenging operational conditions.

Installation and Maintenance Best Practices

Proper Installation Procedures

Successful installation of double mechanical seals requires adherence to specific procedures that ensure optimal performance and service life. Proper shaft alignment, accurate dimensional measurements, and careful handling of sealing components are critical factors that influence long-term reliability. Installation procedures must also account for the complexity of barrier fluid systems and associated piping connections.

The installation process includes verification of shaft runout, impeller balance, and pump casing alignment to minimize vibration and mechanical stress on the sealing system. These mechanical considerations are particularly important for double mechanical seals operating in high-speed or high-pressure applications where small deviations can lead to premature failure.

Predictive Maintenance Strategies

Predictive maintenance programs for double mechanical seals focus on monitoring key performance indicators that provide early warning of potential issues. Vibration analysis, temperature monitoring, and barrier fluid condition assessment help maintenance teams identify developing problems before they result in seal failure or equipment damage.

Modern monitoring systems can track seal chamber pressure, barrier fluid flow rates, and temperature differentials to provide real-time insight into seal performance. This data-driven approach enables proactive maintenance scheduling and helps optimize the service intervals for double mechanical seals in various applications.

Economic Advantages and Cost Considerations

Total Cost of Ownership Analysis

While double mechanical seals typically require higher initial investment compared to single seal alternatives, their superior reliability and extended service life often result in lower total cost of ownership. The reduced frequency of maintenance interventions, elimination of unscheduled downtime, and improved process efficiency contribute to significant long-term cost savings.

Economic benefits extend beyond direct maintenance costs to include reduced product loss, environmental compliance advantages, and improved safety performance. These factors become increasingly important in applications where process interruptions or environmental releases could result in substantial financial penalties or reputation damage.

Energy Efficiency and Operational Benefits

Double mechanical seals contribute to improved energy efficiency through reduced friction losses and optimized sealing performance. The precision-engineered sealing faces minimize parasitic power consumption while maintaining effective sealing under all operating conditions. This efficiency advantage becomes more significant in large-scale industrial applications where multiple pumps operate continuously.

Operational benefits include improved process control, reduced emissions, and enhanced equipment reliability. These advantages support overall plant efficiency objectives and contribute to sustainable manufacturing practices that are increasingly important in modern industrial operations.

Future Developments and Technology Trends

Smart Seal Technology Integration

The integration of smart technology into double mechanical seals represents an emerging trend that promises to enhance monitoring capabilities and predictive maintenance effectiveness. Embedded sensors, wireless communication systems, and advanced data analytics enable real-time monitoring of seal performance parameters and automatic notification of maintenance requirements.

These technological advances support the broader trend toward Industry 4.0 implementation in manufacturing facilities, where connected equipment and intelligent monitoring systems optimize operational efficiency and reduce maintenance costs. Smart double mechanical seals can provide valuable data for process optimization and equipment reliability programs.

Advanced Materials and Coating Technologies

Ongoing research in materials science continues to produce new options for double mechanical seals that offer improved performance in extreme conditions. Nanostructured coatings, advanced ceramics, and hybrid material systems provide enhanced wear resistance, reduced friction, and improved chemical compatibility.

These material advances enable double mechanical seals to operate effectively in increasingly demanding applications while extending service life and reducing maintenance requirements. The development of application-specific material solutions ensures optimal performance across diverse industrial sectors and operating conditions.

FAQ

What are the main advantages of double mechanical seals over single mechanical seals in high-pressure applications

Double mechanical seals provide superior pressure handling capabilities through their dual sealing arrangement, which distributes pressure loads across multiple surfaces and reduces stress concentration. This design enables operation at pressures exceeding 300 PSI while providing redundant protection against leakage. The dual configuration also offers enhanced reliability, as the secondary seal continues to provide protection if the primary seal experiences wear or damage.

How do double mechanical seals maintain performance in high-temperature environments

Double mechanical seals excel in high-temperature applications through advanced heat dissipation technology and specialized materials that maintain dimensional stability at elevated temperatures. The dual sealing arrangement creates multiple heat dissipation paths, while barrier fluid systems provide additional cooling and lubrication. These features enable reliable operation at temperatures up to 500°F in many applications while preventing thermal-related failures.

What maintenance considerations are specific to double mechanical seals

Double mechanical seals require specialized maintenance attention to barrier fluid systems, dual sealing interfaces, and associated monitoring equipment. Maintenance programs should include barrier fluid condition monitoring, seal chamber pressure verification, and temperature differential tracking. Predictive maintenance strategies using vibration analysis and real-time monitoring systems help identify potential issues before they result in seal failure or equipment damage.

How do material selection criteria differ for double mechanical seals compared to single seals

Material selection for double mechanical seals must consider compatibility requirements for both process fluids and barrier fluid systems, as well as the interactions between primary and secondary sealing elements. Advanced materials such as silicon carbide, tungsten carbide, and specialized ceramics are often required for seal faces, while secondary sealing elements must provide chemical resistance and temperature stability. The selection process must account for the complexity of dual sealing arrangements and ensure long-term compatibility across all system components.

Table of Contents

- Advanced Design Principles of Double Mechanical Seals

- Temperature Control and Thermal Management

- Industrial Applications and Performance Benefits

- Material Selection and Compatibility Considerations

- Installation and Maintenance Best Practices

- Economic Advantages and Cost Considerations

- Future Developments and Technology Trends

-

FAQ

- What are the main advantages of double mechanical seals over single mechanical seals in high-pressure applications

- How do double mechanical seals maintain performance in high-temperature environments

- What maintenance considerations are specific to double mechanical seals

- How do material selection criteria differ for double mechanical seals compared to single seals