Mga Sistema ng Pag-seal sa Mga Steril at Sensitibong Kapaligiran sa Presyon

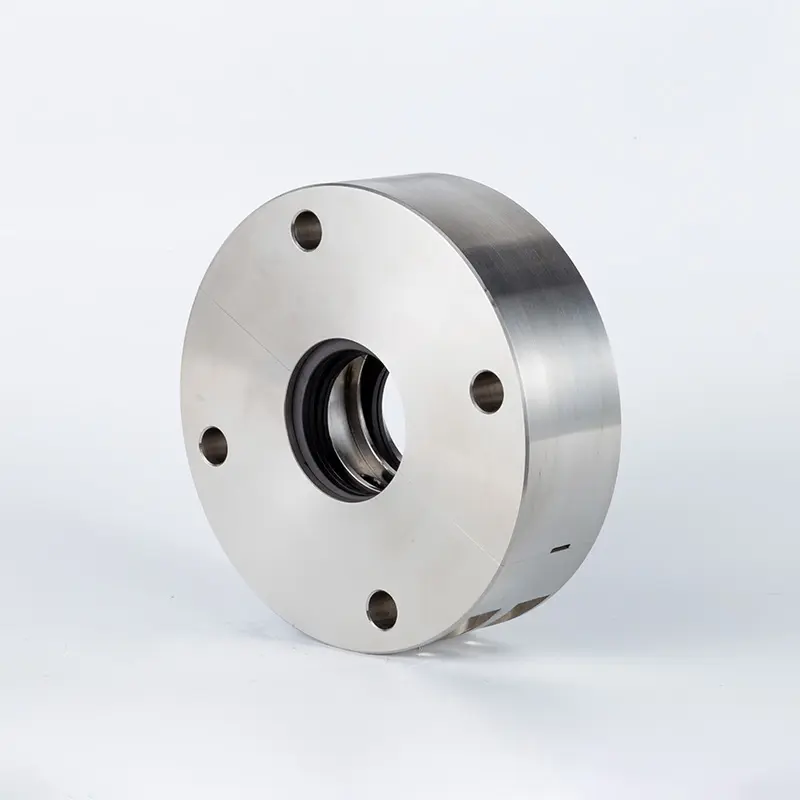

Ang mga Bioreactor ay gumagana sa ilalim ng mahigpit na kontroladong kondisyon, kung saan ang kalinisan, balanse ng presyon, at kahusayan ng agitator ay dapat magkakasabay nang maayos. Isa sa mga kritikal na bahagi na nagpapayari sa balanse na ito ay ang agitator Seal na kumikilos bilang kapwa pisikal na harang at dinamikong sistema ng pag-seal sa mga sensitibong bioquemikal na kapaligiran. Kapag nagtatrabaho kasama ang mga buhay na kultura, pharmaceutical media, o mga proseso ng fermentasyon, ang kahalagahan ng pagpili at pangangalaga ng isang mataas na performans na agitator Seal hindi maitataas ang sapat. Kailangang pamahalaan ng mga seal na ito ang mahihirap na mekanikal, kemikal, at thermal na presyon habang tinitiyak ang zero contamination—na nagpapagawa sa mga hamon na natatangi at maraming anyo sa mga sistema ng bioreactor.

Natatanging Hamon sa Kapaligiran ng Bioreactor

Presyon, Temperatura, at Kailangan sa Kaserohan

Ang mga bioreactor ay madalas na gumagana sa ilalim ng positibo at negatibong presyon depende sa yugto ng fermentasyon o produksyon. Ang mga pagbabagong ito ay lumilikha ng madalas na axial movement at deflection ng shaft na maaaring masira ang sealing interface. Ang agitator Seal dapat manatiling gumagana sa pamamagitan ng mga siklo ng presyon nang hindi nagpapata leaks o pagkawala ng produkto.

Ang mga pagbabago ng temperatura, karaniwang nangyayari sa mga proseso ng sterilization-in-place (SIP) at clean-in-place (CIP), ay maaaring magdulot ng paglaki at pag-urong ng mga bahagi ng pangkabit. Dahil dito, mahalaga ang pagpili ng materyales at ang thermal stability. Bukod dito, ang pagpapanatili ng kalinisan sa buong operasyon at mga proseso ng paglilinis ay nangangailangan ng mga pangkabit na nakakatagpo ng pagpasok ng mikrobyo habang nakakatagal ng paulit-ulit na pagbabago ng temperatura.

Kakayahan sa Pakikipag-ugnayan sa Biological Media

Madalas na mayaman sa mga protina, enzyme, at iba pang sensitibong sangkap ang mga biological media na ginagamit sa bioreactors. Maaaring dumikit, maging kristal, o mag-degrade ang mga sangkap na ito sa interface ng pangkabit. Kung ang isang agitator Seal nagpapapasok o nagtatago ng produkto, maaaring magdulot ito ng panganib sa kontaminasyon o pagbuo ng biofilm—na parehong hindi tinatanggap sa mga GMP (Good Manufacturing Practice) na kapaligiran.

Dapat ding iwasan ng mga pangkabit ang pagbubuga ng mga maliit na butil o paglalabas ng mga materyales sa produkto. Samakatuwid, agitator Seal dapat na sumunod sa FDA ang mga materyales at madalas na sertipikado sa ilalim ng USP Class VI o mga katulad na pamantayan. Ang anumang pagbaba sa pagkakatugma ay maaapektuhan ang produksyon at pagsunod sa regulasyon.

Mga Hamon sa Mekanikal at Operasyunal ng Agitator Seals

Di-pagkakatugma ng Shaft at Agitation Torque

Sa mga malalaking bioreactor, ang pag-igting at di-pagkakatugma ng shaft ay halos hindi maiiwasan dahil sa taas ng sisidlan at mga puwersa na kasangkot sa proseso ng paghahalo. Ang mga tensyon sa mekanikal na ito ay maaaring magdulot ng hindi pantay na pagkarga sa agitator seal, na nagreresulta sa mabilis na pagsusuot ng mukha ng seal o kabiguan nito.

Ang mga agitator seal ay dapat magkasya sa pagbabagong mekanikal na ito sa pamamagitan ng mga tampok tulad ng fleksibleng bellows, mga gumagalaw na mukha, o mga integrated bearing system na nagpapanatili ng katatagan ng seal sa ilalim ng galaw. Ang torque na nabuo ng makapal na biological media o mga proseso ng pagbuo ng bula ay maaaring dagdagan ang tensyon sa mga mukha ng seal, kaya kinakailangan ang mga disenyo na may mas mataas na kakayahan sa pagdadala ng beban.

Tuyong Pagpapatakbo at Mahinang Pagpapadulas

Ang isa sa mga karaniwang sanhi ng kabiguan ng selyo ng agitator ay ang dry run. Sa mga bioreaktor, maaaring mangyari ito sa panahon ng mga operasyon na may mababang pagpuno, hindi inaasahang mga pag-aalis ng batch, o hindi tamang mga pagkakasunud-sunod ng pagsisimula. Kung walang lubrication, ang mga mukha ng selyo ay maaaring mabilis na sobra ang init, na humahantong sa pag-aalsa, pag-aakyat, o kahit na malaking pagkabigo.

Upang mabawasan ang ganitong sitwasyon, kasama sa mga seal system ang flush ports, barrier fluids, o mga mekanismo para sa proteksyon sa dry-running. Ang pagpili ng agitator seal na kayang tumanggap ng maikling dry running o mayroong self-lubricating materials ay nagbibigay ng karagdagang proteksyon sa mga proseso na kritikal sa produksyon.

Mga Limitasyon sa Materyales at Disenyo sa Mga Aplikasyon ng Bioreactor

Pagkabulok ng Materyales at Hindi Pagkakatugma sa Kemikal

Ang proseso ng paglilinis ng bioreactor ay kasama ang paggamit ng matitinding kemikal tulad ng caustic solutions, acids, at peracetic acid. Sa paglipas ng panahon, maaaring masira ang elastomers, lumambot ang gaskets, o magkaroon ng pitting ang metallic components ng agitator seal. Ang resulta nito ay pagkawala ng integridad ng sealing at mas mataas na panganib ng kontaminasyon.

Ang pagpili ng mga seal na gawa sa mga materyales na nakakalaban sa kemikal tulad ng Kalrez, EPDM, o PTFE, at mga metal tulad ng Hastelloy o titanium, ay maaaring magpalawig ng habang-buhay at mabawasan ang dalas ng pagpapalit. Gayunpaman, dapat laging i-verify ang pagkakatugma ng materyales sa mga tiyak na sangkap sa paglilinis at biyolohikal na media upang maiwasan ang hindi sinasadyang pagkasira.

Mga Hamon sa Pagpili ng Mukha ng Seal

Dapat magbigay ang mga materyales ng mukha ng seal ng mababang pagkakagulo habang nakakatiis ng pagpapakilos, pagkalantad sa kemikal, at biyolohikal na pagkakadumi. Karaniwang mga kombinasyon ay karbon kumpara sa silicon carbide o ceramic kumpara sa tungsten carbide. Ang bawat isa ay may mga kompromiso sa tuntunan ng paglaban sa pagsusuot, pagkakatugma sa kemikal, at pag-expande dahil sa init.

Ang pagpili ng hugis ng mukha ay may mahalagang papel din. Angg angkop ang mga datar na mukha para sa malinis na likido ngunit maaaring hindi maganda ang pagganap kapag may biglang pagtaas ng presyon. Ang mga disenyo na pabilog o spiral ay nagpapabuti sa pagpapanatili ng pelikula ng likido, lalo na sa mga aplikasyon ng bioreactor na may mababang bilis at mataas na karga. Ang tamang disenyo ng mukha ay direktang nakakaapekto sa haba ng buhay ng selyo at katiyakan ng proseso.

Mga Panganib sa Operasyon at Mga Isyu Tungkol sa Pagpapanatili

Di-madalas na Pagsusuri sa Selyo

Sa produksyon ng biopharmaceutical, ang patuloy na operasyon sa mahabang kurot ay nasa norma. Ibig sabihin nito, ang mga selyo ng agitator ay kadalasang inaasahan na magtatagal ng ilang linggo o buwan nang hindi maaring suriin. Nakakalungkot, ang mahabang oras ng pagpapatakbo ay maaaring magtago ng unti-unting pagkabigo, na baka lang matuklasan pagkatapos ng kontaminasyon o pagkawala ng produkto.

Upang maiwasan ito, ang mga selyo na may port para sa pagmomonitor o smart sensor ay maaaring subaybayan ang presyon, temperatura, at pagtagas sa real-time. Ang mga ganitong diskarte na batay sa datos ay nagpapadali sa pagtukoy ng pagsusuot bago ito maging critical, na sumusuporta sa mga modelo ng predictive maintenance.

Pagsusuot ng Selyo sa Panahon ng Paglilinis

Ang paulit-ulit na pagkakalantad sa mataas na presyon ng singaw, mga siklo ng bakuwum, at mga kemikal sa paglilinis sa panahon ng operasyon ng SIP at CIP ay maaaring mapabilis ang pagsusuot ng selyo. Ang thermal cycling ay maaaring magdulot ng pagkamatigas ng mga elastomer, samantalang ang mekanikal na pagkilos ng paglilinis ay maaaring sumalanta sa mga mababagong mukha ng selyo. Kung ang selyo ng agitator ay hindi idinisenyo upang makatiis sa mga paulit-ulit na siklong ito, mabilis na bumababa ang kanyang pagganap.

Ang paggamit ng mga selyo na partikular na idinisenyo para sa CIP/SIP na kakaugnay ay nagsisiguro ng matagalang tibay. Ang mga selyong ito ay karaniwang may mga materyales na may rating para sa autoclave at mga dinagdagan na elemento ng disenyo na nagpapanatili ng integridad ng selyo kahit pagkatapos ng daan-daang mga siklo.

Mga Isinasaalang-alang sa Pagpaplano para sa mga Selyo ng Bioreactor

Single vs. Double Mechanical Seal Designs

Ang mga single mechanical seals ay kadalasang mas simple at kompakto ngunit maaaring hindi sapat sa mga demanding na bioreactor application dahil sa limitadong containment. Kung ikukumpara, ang double mechanical seals na may pressurized barrier fluids ay nag-aalok ng mas mahusay na paghihiwalay at tumutulong na mapanatili ang isang malinis na seal interface sa pamamagitan ng pagpigil sa media ingress.

Ang paggamit ng double agitator seals ay nagpapahintulot din ng mas mahusay na thermal control, lalo na sa mga application na kasama ang foaming, viscous media, o highly reactive ingredients. Bagama't mas kumplikado ang kanilang pag-install at support systems, ang kanilang reliability at kaligtasan ay nagpapahint justify sa pamumuhunan sa mga kritikal na proseso.

Seal Support Systems at Monitoring

Ang epektibong operasyon ng double agitator seals ay nakasalalay sa mga well-maintained seal support systems. Ang mga sistemang ito ay namamahala ng barrier fluid pressure, temperatura, at kalinisan. Ang anumang pagbabago sa mga parameter na ito ay maaaring makompromiso ang sealing effectiveness at dagdagan ang pagsusuot.

Ang mga automated na systema ng suporta at control units ay makapapadali sa pamamahala ng barrier fluid at mababawasan ang posibilidad ng pagkakamali ng tao. Ang ilang advanced na configuration ay pagsasama-samahin ang mga sensor ng temperatura at ipapadala ang real-time na datos sa mga systema ng kontrol, na nag-trigger ng mga alarm o shutdown kapag may natuklasang anomalya.

Ang Kahalagahan ng Kaalaman ng Nagbibili at Pagpapasadya

Mga Dinisenyong Seal na Naayon sa Mga Espesyalisadong Reactor

Ang mga bioreactor configuration ay nag-iiba-iba, mula sa mga maliit na lab fermenters hanggang sa malalaking production vessel. Ang bawat isa ay may iba't ibang mga hamon sa pagse-seal, kaya ang mga solusyon na readymade ay hindi sapat sa maraming kaso. Ang pakikipagtulungan sa isang tagabenta ng seal na nakauunawa sa tiyak na geometry ng reactor, operating cycle, at mga katangian ng media ay magreresulta sa mas magandang resulta.

Ang mga pasadyang solusyon para sa agitator seal ay maaaring isama ang mga pag-upgrade ng materyales na partikular sa site, mga pagbabago sa sukat ng shaft, at integrasyon ng mga sistema ng pagmamanman. Ang pasadyang diskarteng ito ay nagsisiguro ng pagkakasunod-sunod, pinahuhusay ang pagganap, at pinapahaba ang serbisyo ng buhay sa mga kumplikadong kapaligiran sa produksyon.

Pagsasanay at Suporta sa Teknikal para sa Maayos na Pag-integrate

Ang tamang pag-install at pagpapanatili ng agitator seals ay nangangailangan ng espesyalisadong kaalaman, lalo na sa mga reguladong industriya. Ang pagsasanay sa mga tauhan ng planta tungkol sa pinakamahusay na kasanayan, pagdidiskubre ng pagkabigo, at kalibrasyon ng sistema ay makatutulong upang i-maximize ang haba ng buhay ng seal at ang oras ng operasyon ng proseso.

Bukod dito, ang pag-access sa teknikal na suporta sa real-time ay nagpapahintulot ng mas mabilis na tugon sa mga isyu ng seal, binabawasan ang pagkawala ng produksyon at pinapanatili ang garantiya ng kalidad. Ang isang bihasang nagbebenta ay nagbibigay hindi lamang ng produkto, kundi ng kompletong solusyon sa pag-seal na ginawa para sa pangmatagalang katiyakan.

FAQ

Ano ang nagiging sanhi ng karamihan sa pagkabigo ng agitator seal sa bioreactor?

Kasama sa karaniwang dahilan ang dry running, hindi tamang pagkakaposisyon ng shaft, pagkabagabag ng mga materyales ng seal dahil sa kemikal, at thermal stress mula sa mga CIP/SIP cycle. Ang mekanikal na pagsusuot dahil sa mababang pagpapadulas o hindi tamang pag-install ay isang karaniwang salik din.

Gaano kadalas dapat palitan ang agitator seals sa mga bioreactor na aplikasyon?

Ang dalas ng pagpapalit ng seal ay nakadepende sa kondisyon ng operasyon at lakas ng paglilinis. Ang mataas na dalas ng CIP/SIP cycle at mga materyales na nakakapinsala ay maaaring nangangailangan ng mas madalas na inspeksyon at taunang pagpapalit, samantalang ang mga maayos na pinapanatiling sistema ay maaaring mas matagal.

Kinakailangan ba ng double mechanical seals sa lahat ng bioreactor na proseso?

Hindi lagi, ngunit malakas na inirerekomenda ito sa mga mataas na panganib na aplikasyon na kinasasangkutan ng mapanganib na media, sterile na produksyon, o kritikal na containment. Ang double agitator seals ay nag-aalok ng karagdagang proteksyon laban sa kontaminasyon at mga pagkabigo na may kaugnayan sa presyon.

Anong mga materyales ang pinakamahusay para sa agitator seals sa sterile na kapaligiran?

Ang mga materyales tulad ng PTFE, EPDM, at Kalrez para sa mga elastomer, at silicon carbide o Hastelloy para sa mga matigas na bahagi, ay karaniwang ginagamit dahil sa kanilang pagtutol sa mga kemikal, mataas na temperatura, at paglago ng mikrobyo.

Talaan ng Nilalaman

- Mga Sistema ng Pag-seal sa Mga Steril at Sensitibong Kapaligiran sa Presyon

- Natatanging Hamon sa Kapaligiran ng Bioreactor

- Mga Hamon sa Mekanikal at Operasyunal ng Agitator Seals

- Mga Limitasyon sa Materyales at Disenyo sa Mga Aplikasyon ng Bioreactor

- Mga Panganib sa Operasyon at Mga Isyu Tungkol sa Pagpapanatili

- Mga Isinasaalang-alang sa Pagpaplano para sa mga Selyo ng Bioreactor

- Ang Kahalagahan ng Kaalaman ng Nagbibili at Pagpapasadya

-

FAQ

- Ano ang nagiging sanhi ng karamihan sa pagkabigo ng agitator seal sa bioreactor?

- Gaano kadalas dapat palitan ang agitator seals sa mga bioreactor na aplikasyon?

- Kinakailangan ba ng double mechanical seals sa lahat ng bioreactor na proseso?

- Anong mga materyales ang pinakamahusay para sa agitator seals sa sterile na kapaligiran?