Enhancing the Durability of Sealing Systems in Petrochemical Environments

In the demanding conditions of petrochemical plants, maintaining the integrity of sealing systems is crucial. Seals for seal applications must withstand harsh chemical exposure, extreme temperatures, and high pressures. Proper selection, installation, and maintenance of seals are fundamental to ensuring operational reliability and minimizing downtime. This article explores the best practices for achieving longevity in seals for seal systems used in petrochemical facilities, focusing on factors that influence performance and practical steps to extend seal life.

Understanding the Importance of Seals in Petrochemical Plants

Role of Seals in Petrochemical Processing

Seals serve as the primary barriers preventing leaks of hazardous substances, protecting both equipment and personnel. In petrochemical plants, seals help contain volatile fluids, corrosive chemicals, and gases under high pressures. Effective seals reduce the risk of environmental contamination, equipment damage, and costly shutdowns. Their performance directly impacts plant safety and operational efficiency.

Seals for seal applications often encounter aggressive chemicals, abrasive materials, and fluctuating operating conditions. Therefore, understanding the operational environment is essential to choosing the right sealing technology and materials.

Challenges Faced by Sealing Systems

Sealing systems in petrochemical plants face several challenges including chemical degradation, thermal cycling, mechanical wear, and pressure fluctuations. Exposure to hydrocarbons, acids, and solvents can deteriorate seal materials over time, leading to leaks. Thermal expansion and contraction can compromise seal seating, while abrasive particles can erode sealing surfaces.

Additionally, installation errors and improper maintenance accelerate seal failure. These factors make it imperative to adopt a comprehensive approach encompassing material selection, design optimization, installation best practices, and routine inspection.

Selecting Seals for Petrochemical Applications

Material Considerations for Seals

Choosing the correct material for seals in petrochemical plants is fundamental to their longevity. Materials such as PTFE, elastomers like Viton and EPDM, and metal seals are commonly used due to their chemical resistance and mechanical properties.

PTFE seals provide excellent resistance to a broad range of chemicals but may lack flexibility under certain conditions. Elastomeric seals offer good sealing capability and elasticity but must be selected carefully based on chemical compatibility. Metal seals, including spiral wound or ring-type, provide high-temperature and pressure resistance but may require precise installation.

Understanding the chemical environment and operating conditions is key to selecting the appropriate seal material that balances durability and performance.

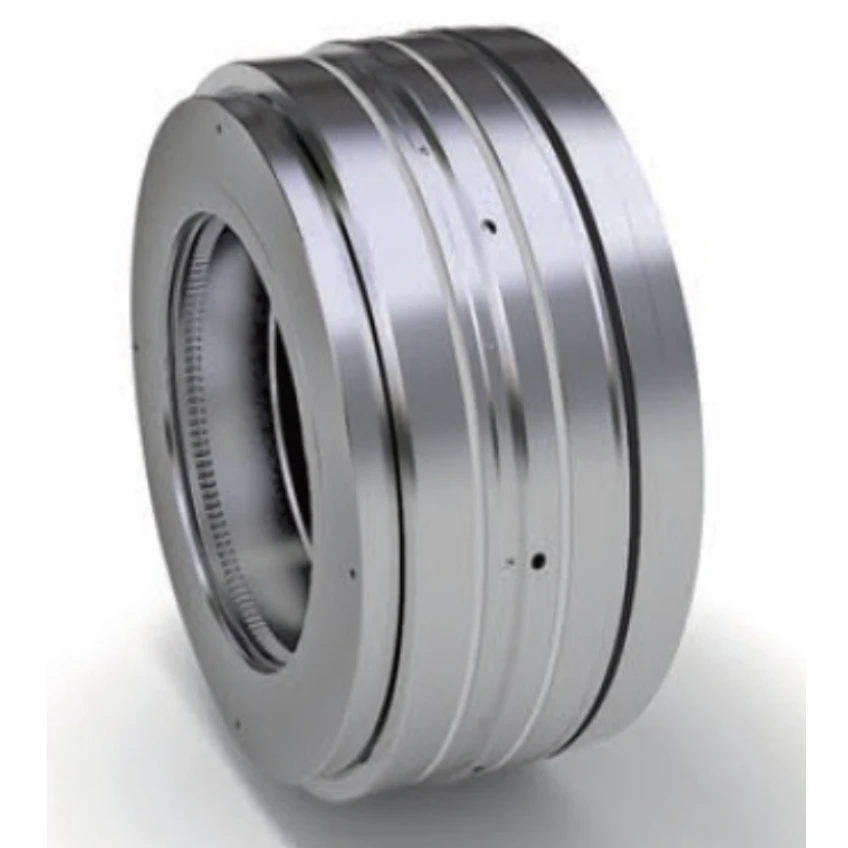

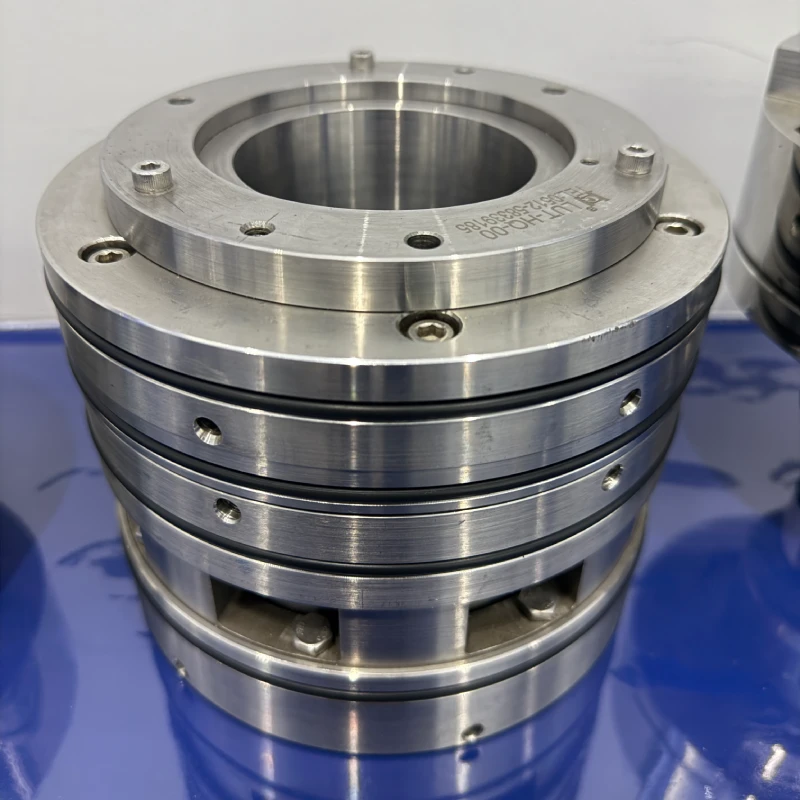

Seal Design and Compatibility

Seal design also influences performance. Single, double, or cartridge seals each have their benefits and limitations depending on application specifics. Double mechanical seals, for example, provide an additional barrier against leakage and are often preferred in high-risk areas of petrochemical plants.

Compatibility with equipment such as pumps, compressors, and valves should be assessed to ensure proper fit and function. Proper seal face geometry and spring design contribute to uniform load distribution and reduce premature wear.

Installation Practices for Optimized Seal Performance

Importance of Professional Installation

Even the best seal cannot perform well if not installed correctly. Professional installation ensures seals are seated properly without distortion or damage. Use of calibrated tools and adherence to manufacturer guidelines prevent issues such as misalignment and uneven compression.

Before installation, cleaning sealing surfaces and inspecting equipment for wear or damage is vital. Lubrication, when appropriate, aids in preventing dry running during startup, protecting both seal faces and equipment.

Environmental and Operational Adjustments

Adjusting operating conditions during and immediately after seal installation can extend seal life. Gradual ramp-up of pressure and temperature reduces stress on new seals. Monitoring vibration and ensuring alignment of rotating equipment also helps maintain seal integrity.

Control of environmental factors such as dust and moisture around sealing points prevents contamination that can cause abrasion or corrosion.

Maintenance Strategies to Extend Seal Life

Regular Inspection and Monitoring

Scheduled inspections allow early detection of seal wear, leakage, or material degradation. Visual checks, vibration analysis, and thermal imaging are effective monitoring methods. Timely intervention prevents minor issues from escalating into costly failures.

Using condition monitoring technologies can provide real-time data, enabling predictive maintenance and reducing unplanned downtime.

Repair and Replacement Protocols

Deciding when to repair or replace seals is crucial. Minor damages may be repairable, but often replacement is the safer choice to maintain plant safety. Keeping a stock of commonly used seals facilitates quick replacement, minimizing operational interruptions.

Documentation of seal performance and maintenance history supports continuous improvement and informed decision-making for future seal selections.

Advantages of Adopting Advanced Sealing Technologies

Benefits of Innovative Materials and Designs

Advancements in seal materials, such as fluoropolymer composites and high-performance elastomers, offer enhanced chemical and thermal resistance. New seal designs focus on reducing friction, improving face alignment, and increasing tolerance to pressure fluctuations.

Integrating these innovations into petrochemical plants helps reduce leakage rates and maintenance frequency, contributing to cost savings and sustainability goals.

Company-Specific Expertise and Solutions

Companies specializing in petrochemical sealing solutions often provide customized designs tailored to specific plant needs. Leveraging their expertise ensures that seals for seal applications not only meet but exceed industry standards.

This approach optimizes plant performance, enhances safety, and provides reliable support for ongoing maintenance and technical challenges.

FAQ

What factors most affect the lifespan of seals in petrochemical plants?

Several factors influence seal longevity, including chemical compatibility, temperature extremes, pressure variations, and mechanical wear. Proper material selection and installation practices are critical to mitigate these impacts.

How often should seals in petrochemical plants be inspected?

Inspection frequency depends on operating conditions and criticality of the sealed equipment. Generally, regular visual inspections monthly and comprehensive checks during scheduled maintenance shutdowns are recommended.

Can seals be repaired or should they always be replaced when damaged?

Minor seal damage might be repairable in some cases, but replacement is usually advised to maintain safety and performance standards. Keeping a stock of replacement seals helps minimize downtime.

What innovations are improving sealing technology in the petrochemical industry?

Advancements in seal materials like fluoropolymer composites and enhanced elastomers, along with improved seal designs that reduce friction and handle pressure better, are key innovations extending seal life and reliability.

Table of Contents

- Enhancing the Durability of Sealing Systems in Petrochemical Environments

- Understanding the Importance of Seals in Petrochemical Plants

- Selecting Seals for Petrochemical Applications

- Installation Practices for Optimized Seal Performance

- Maintenance Strategies to Extend Seal Life

- Advantages of Adopting Advanced Sealing Technologies

- FAQ