The Growing Demand for Precision Sealing in Industrial Equipment

In modern industrial processes, efficiency and reliability are more critical than ever. Equipment must operate under extreme pressure, temperature, and chemical exposure, requiring components that ensure smooth, safe, and leak-free performance. One such component is the agitator seal, which plays a vital role in maintaining system integrity and preventing contamination. With increased customization demands and operational complexity, the market for high-performance sealing systems is expanding rapidly. This growth is driving a surge in interest in agitator seal pressure manufacturers capable of delivering tailored solutions.

Overview of Agitator Seal Pressure Systems

Role of agitator seal pressure components

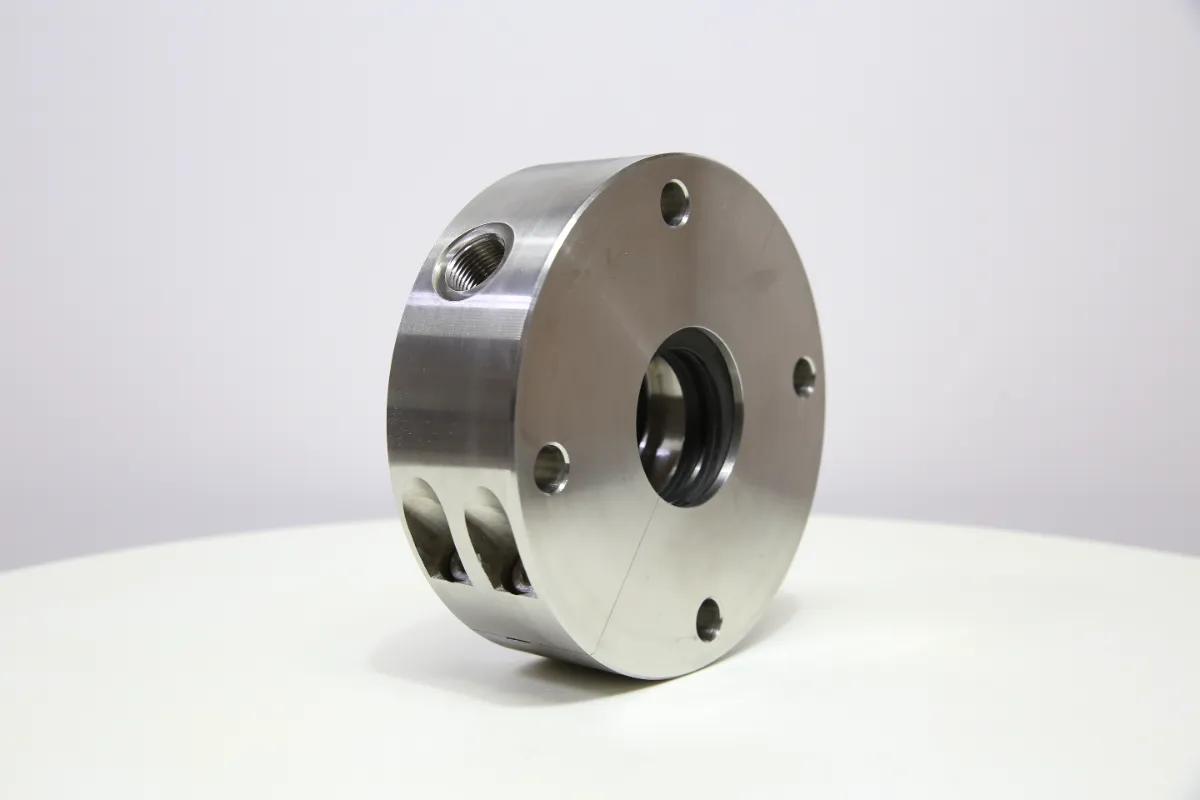

Agitator seal pressure systems are engineered to manage and maintain pressure integrity around rotating shafts in agitators, mixers, and reactors. These seals prevent leakage of hazardous or sensitive materials, contributing to safety, regulatory compliance, and process consistency. Especially in industries such as pharmaceuticals, chemicals, food processing, and petrochemicals, agitator seal pressure systems play an indispensable role.

Seals must perform reliably under varied conditions, including vacuum environments, high-speed rotations, and fluctuating internal pressures. This complexity makes the quality and design of the seal a determining factor in the overall system’s efficiency.

Key design parameters and challenges

Agitator seal pressure manufacturers focus on multiple parameters when designing their products, such as temperature resistance, pressure thresholds, chemical compatibility, and the ability to withstand abrasive or corrosive environments. Engineers must carefully evaluate shaft movement, product viscosity, and cleaning procedures (CIP/SIP).

The challenges of designing effective agitator seals increase when customization is required for specific applications. This is where manufacturers offering customized sealing solutions provide a competitive advantage.

Benefits of Custom Sealing Solutions in Industrial Applications

Enhanced equipment compatibility and performance

Standard seals may not fit all equipment models or address every process requirement. Custom agitator seal pressure solutions ensure compatibility with unique dimensions, materials, and operational conditions. This tailored approach minimizes the risk of seal failure, enhances system uptime, and supports long-term equipment efficiency.

By optimizing seal design based on precise application parameters, agitator seal pressure manufacturers can help clients reduce maintenance frequency, avoid unplanned downtime, and maintain better control over internal pressure fluctuations.

Adaptability to industry-specific demands

Industries have varying regulations, hygiene requirements, and operating pressures. For instance, pharmaceutical production requires aseptic sealing with stringent validation protocols, while chemical manufacturing demands high resistance to solvents and corrosives. Customized agitator seal pressure solutions cater to these specific needs without compromise.

This level of customization supports GMP compliance, improves safety standards, and promotes overall product quality. Manufacturers that specialize in such tailored designs add substantial value to industrial partners seeking to enhance operational excellence.

Technologies and Innovations in Agitator Seal Pressure Design

Use of advanced materials and coatings

Materials used in agitator seal pressure systems have evolved considerably. Manufacturers are increasingly leveraging high-grade alloys, carbon composites, ceramics, and elastomers with specialized coatings to deliver superior performance. These materials help manage thermal expansion, reduce friction, and extend seal life.

Advanced coatings and treatments improve surface durability and enable better performance in abrasive or chemically aggressive environments. Selecting the right combination of materials and finishes is key to designing effective and long-lasting sealing systems.

Integration with monitoring and automation systems

Modern agitator seal pressure systems are often integrated with digital monitoring tools and sensors. These smart seals enable real-time monitoring of seal performance, pressure levels, and potential wear or damage. Manufacturers offering digital integration enhance predictive maintenance capabilities and reduce the risk of unexpected failures.

As Industry 4.0 advances, customized agitator seal pressure solutions equipped with IoT connectivity and data analytics are becoming more prevalent. This innovation helps manufacturers and end-users alike make informed decisions and proactively maintain system health.

Selecting the Right Agitator Seal Pressure Manufacturer

Experience and technical expertise

Choosing the right manufacturer involves more than reviewing product catalogs. Agitator seal pressure manufacturers with a proven track record in multiple industries bring essential expertise in design, materials science, testing, and application engineering. Their ability to understand process-specific requirements ensures the seal is both functional and durable.

Experienced manufacturers often have extensive knowledge of industry certifications, cleanroom production, and pressure testing standards, which are critical in high-risk or regulated sectors. Collaborating with such partners can streamline procurement and integration processes.

Capability for customization and after-sales support

One of the most important aspects to consider is a manufacturer’s ability to develop custom sealing solutions. This includes support for prototyping, material selection, seal configuration, and installation guidance. Custom designs should align with the customer’s operational goals, system limitations, and maintenance strategies.

After-sales services such as training, technical support, spare parts availability, and reconditioning options also set high-quality agitator seal pressure manufacturers apart. Ongoing support ensures the seal’s long-term reliability and effectiveness in daily operation.

Applications Across Multiple Industries

Pharmaceutical and biotechnology sectors

In pharmaceutical production, maintaining a sterile and contaminant-free environment is essential. Agitator seal pressure systems in bioreactors and process vessels must comply with rigorous FDA and EU regulations. Custom seals allow for hygienic design, easy sterilization, and material compatibility with sensitive products.

These systems are typically made from FDA-approved materials and are designed to meet aseptic standards while resisting pressure and temperature fluctuations during steam sterilization or cleaning cycles.

Chemical and petrochemical manufacturing

The chemical industry relies on robust sealing systems to handle a wide range of aggressive media, from acids and alkalis to solvents and slurries. Agitator seal pressure manufacturers serving this sector must provide seals that can withstand both corrosive and abrasive environments.

Custom-engineered seals ensure safe operation, minimize leakage risks, and provide long-term reliability. These solutions also help mitigate environmental concerns associated with chemical spills or emissions.

Future Trends in Sealing Technology and Industrial Solutions

Shift toward sustainable and eco-friendly designs

Sustainability has become a core priority in industrial manufacturing. Agitator seal pressure manufacturers are responding by developing seals made from recyclable or environmentally friendly materials. Additionally, they aim to reduce waste during manufacturing and extend the usable life of sealing systems.

Designs that minimize energy consumption and promote efficient fluid management contribute to greener operations. Eco-conscious sealing solutions are increasingly being adopted by companies seeking to meet environmental goals.

Emphasis on rapid prototyping and agile manufacturing

Customization once meant long lead times and high costs. Today, advancements in rapid prototyping, 3D modeling, and CNC machining allow manufacturers to deliver customized agitator seal pressure solutions with greater speed and flexibility. These capabilities improve responsiveness to market demands and reduce time-to-market.

Agile manufacturing also enables iterative testing and refinement, ensuring that each seal meets exact performance criteria before full-scale production begins.

FAQ

What are the main industries that use agitator seal pressure systems?

Agitator seal pressure systems are commonly used in pharmaceuticals, food and beverage, chemicals, cosmetics, petrochemicals, and biotechnology. These industries require precise sealing solutions to ensure process safety and product integrity.

Why is customization important for agitator seal pressure components?

Customization allows seals to be tailored to specific equipment, operating conditions, and industry requirements. This ensures optimal performance, longer seal life, and reduced risk of failure in demanding environments.

How do I choose the right agitator seal pressure manufacturer?

Look for manufacturers with proven industry experience, customization capabilities, strong material expertise, and reliable after-sales support. Certifications and compliance with industry standards are also key considerations.

Can agitator seal pressure systems be integrated with digital monitoring?

Yes, many modern agitator seal pressure solutions come with sensors and monitoring tools that enable predictive maintenance and real-time performance tracking. This helps reduce downtime and improve operational efficiency.

Table of Contents

- The Growing Demand for Precision Sealing in Industrial Equipment

- Overview of Agitator Seal Pressure Systems

- Benefits of Custom Sealing Solutions in Industrial Applications

- Technologies and Innovations in Agitator Seal Pressure Design

- Selecting the Right Agitator Seal Pressure Manufacturer

- Applications Across Multiple Industries

- Future Trends in Sealing Technology and Industrial Solutions

- FAQ