Importance of Sealing Integrity in Industrial Processing Environments

In chemical and pharmaceutical plants, the integrity of sealing systems is vital for ensuring safety, process efficiency, and product quality. A small leakage or contamination due to failed seals can compromise entire production batches, cause equipment failure, or lead to regulatory non-compliance. That’s why agitator seal pressure systems play such an essential role in modern industrial processing. These systems are designed not only to withstand extreme operational conditions but also to protect sensitive formulations and volatile chemicals.

Agitator seal pressure systems function by providing a pressurized barrier around rotating shafts in tanks and reactors, preventing internal materials from leaking and external contaminants from entering. The importance of these systems becomes even more pronounced in sectors where sterility, purity, and controlled environments are non-negotiable, such as pharmaceuticals and high-grade chemicals.

Specialized Requirements of the Chemical Industry

Managing aggressive media and volatile reactions

In chemical manufacturing, handling hazardous and reactive substances is a routine task. Agitator seal pressure systems are specifically engineered to accommodate this reality. These systems must resist aggressive solvents, corrosive acids, and abrasive particles that could erode standard seals. High-performance sealing materials such as PTFE, Viton, and Hastelloy are commonly used to ensure long-lasting performance.

Seal designs in the chemical sector also take into account rapid thermal cycling and high-pressure fluctuations that occur during batch reactions. The sealing system must maintain integrity even when exposed to fluctuating temperatures and sudden changes in viscosity or pH levels. Agitator seal pressure systems used in such environments must demonstrate not only chemical resistance but also mechanical durability.

Ensuring leak prevention and environmental compliance

With stricter environmental regulations, chemical plants must now adopt technologies that minimize emissions and prevent contamination. Agitator seal pressure systems contribute significantly to leak-free operation. They also support double mechanical seals and buffer systems that provide an added layer of protection.

A well-designed agitator seal pressure system enhances compliance with EPA and similar standards by containing toxic or volatile compounds within closed systems. In applications where volatile organic compounds (VOCs) or flammable substances are used, the reliability of seals can be a major factor in risk mitigation and safety assurance.

Meeting the Needs of the Pharmaceutical Sector

Sterile process environments and hygienic design

Pharmaceutical manufacturing requires an exceptional level of cleanliness. Agitator seal pressure systems used in this industry must support aseptic processes while complying with GMP (Good Manufacturing Practices), FDA guidelines, and EU Annex 1 requirements. This includes clean-in-place (CIP) and steam-in-place (SIP) capabilities, which are necessary for maintaining sterile environments.

Seals for pharmaceutical applications are typically made with FDA-approved elastomers and surfaces with electropolished finishes to reduce bacterial retention. These systems must also prevent product cross-contamination and maintain integrity throughout multiple production cycles. Agitator seal pressure systems must provide hygienic sealing in bioreactors, fermenters, and other sterile vessels.

Material compatibility and product safety

Pharmaceutical formulations often include sensitive biological materials, active ingredients, and solvents that must not interact with the seal components. Therefore, selecting the right materials for agitator seal pressure systems is crucial. Inappropriate materials could cause leaching, extractables, or degradation that compromises product safety.

Custom-engineered agitator seal pressure systems are frequently employed in this sector to meet specific application requirements, including temperature range, sterilization cycles, and product compatibility. These designs help preserve the efficacy and purity of pharmaceuticals from start to finish.

Key Features of Reliable Agitator Seal Pressure Systems

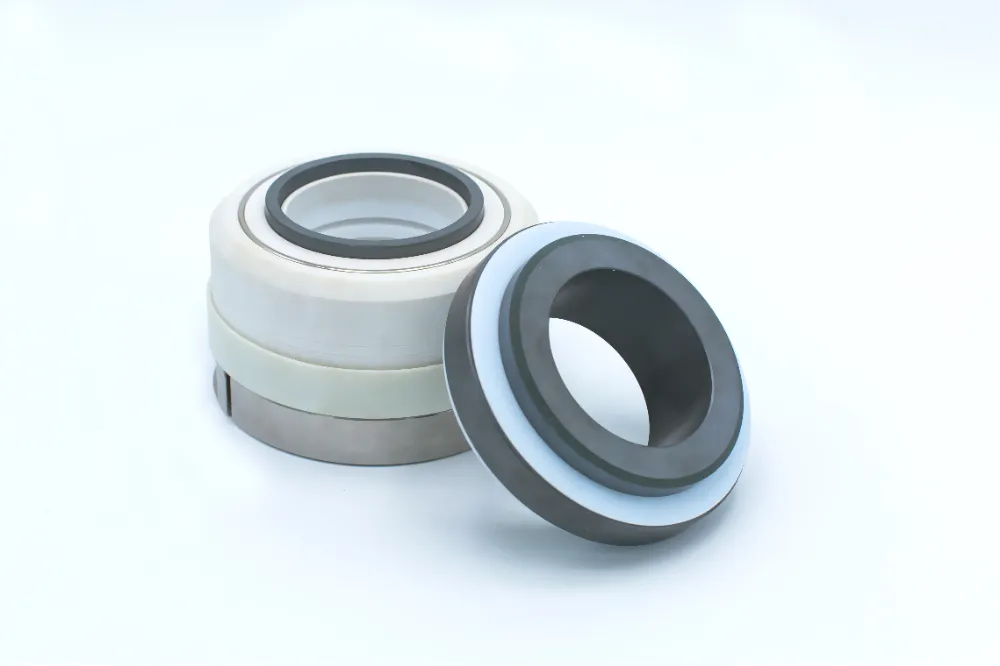

Use of advanced sealing materials and components

The choice of materials significantly affects the performance and longevity of agitator seal pressure systems. High-quality elastomers, carbon graphite, and metal alloys are selected based on the application’s exposure to temperature, pressure, and chemical reactivity. For example, materials must tolerate caustic cleaning agents in pharmaceutical production or withstand hydrofluoric acid in chemical processing.

Mechanical seal components are precision-engineered to ensure minimal friction and optimized contact surfaces. This reduces wear, increases service life, and improves system stability. Modern sealing technologies also incorporate coatings and treatments that resist corrosion and erosion.

Integration with monitoring systems

Today’s advanced agitator seal pressure systems are often designed to interface with digital monitoring systems. These allow real-time observation of seal condition, pressure variations, and temperature changes. Such integration supports predictive maintenance and prevents catastrophic failure.

Digitalized sealing systems also align with Industry 4.0 initiatives, helping plant operators optimize performance while minimizing unplanned downtime. Seals embedded with sensors and connected to SCADA or MES platforms provide alerts and logs that enhance traceability and operational control.

Advantages of Custom Sealing Solutions

Tailored to specific process requirements

Standard seals may not address the complexity of modern chemical and pharmaceutical processes. Custom agitator seal pressure systems are designed to account for unique tank geometries, specific fluid dynamics, and operational cycles. This leads to enhanced process efficiency and improved reliability.

Customized sealing solutions also allow flexibility in terms of materials, pressure ranges, and configurations. Whether a company deals with highly reactive intermediates or requires sterility for live cultures, a tailored agitator seal pressure system ensures optimal compatibility and minimal risk.

Simplified maintenance and extended lifespan

When a seal is specifically designed for a particular application, it is less prone to failure and easier to maintain. Maintenance teams benefit from predictable service intervals and simplified disassembly and cleaning routines. This is especially important in pharmaceutical plants, where equipment validation and documentation are critical.

Custom systems often include modular components that can be replaced independently, reducing repair costs and downtime. By improving serviceability, customized agitator seal pressure systems reduce total cost of ownership and ensure long-term reliability.

Installation and Operational Best Practices

Proper seal selection and system compatibility

Choosing the right agitator seal pressure system begins with understanding the application requirements in detail. This includes fluid properties, process temperatures, pressure variations, and rotational speeds. Mismatched seals can result in premature wear, system inefficiencies, or even catastrophic failure.

Plant engineers must also ensure that seals are compatible with the vessel’s design and agitation method. Vertical, horizontal, and side-entry agitators each require unique sealing solutions. A thorough compatibility assessment is essential for achieving optimal performance.

Routine inspection and performance monitoring

Once installed, regular inspection and condition monitoring are key to ensuring that agitator seal pressure systems perform reliably. Visual checks, sensor data, and routine pressure testing can identify wear or leakage before it becomes critical.

Documented inspection routines and training for maintenance personnel further support long-term seal integrity. Combining proactive monitoring with digital tools allows facilities to maintain high operational efficiency while minimizing unplanned downtime.

FAQ

What industries benefit most from agitator seal pressure systems?

Industries such as chemicals, pharmaceuticals, food and beverage, biotechnology, and cosmetics benefit significantly from these systems due to their need for leak-free, high-integrity process environments.

Why is material selection important in agitator seal pressure systems?

Different applications involve different chemical exposures, pressures, and temperatures. Using the wrong material could lead to seal failure, contamination, or safety risks. Proper material selection ensures reliability and compliance.

Are agitator seal pressure systems customizable?

Yes, many manufacturers offer custom-designed seal solutions tailored to specific process needs, equipment configurations, and industry regulations.

How can digital integration improve seal system performance?

By integrating sensors and real-time monitoring tools, operators can detect early signs of wear, pressure loss, or contamination, allowing preventive maintenance and reducing operational risk.

Table of Contents

- Importance of Sealing Integrity in Industrial Processing Environments

- Specialized Requirements of the Chemical Industry

- Meeting the Needs of the Pharmaceutical Sector

- Key Features of Reliable Agitator Seal Pressure Systems

- Advantages of Custom Sealing Solutions

- Installation and Operational Best Practices

- FAQ